Hello, welcome to Jiangsu Main Machinery Technology Co., Ltd.!

Telephone:0510-86017899 Email:huangqindong@jszhjx.cn

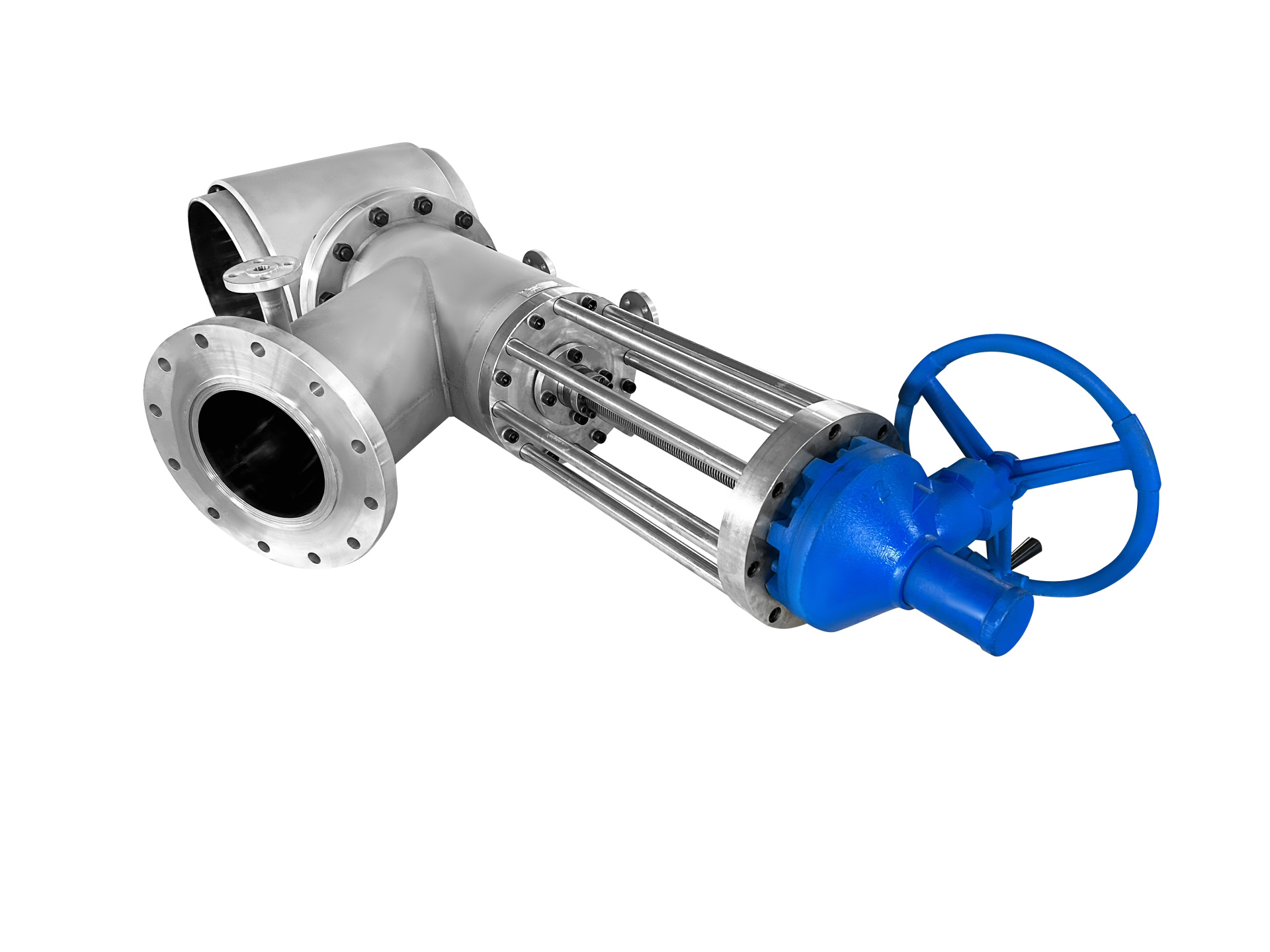

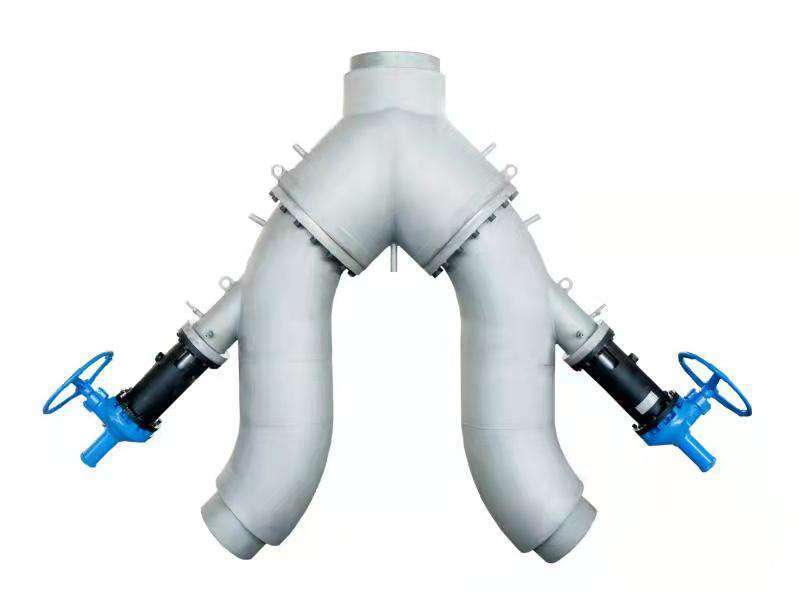

CPF-PE-S Melt filter

With its novel design, superb technology, and rigorous quality inspection, the product is unique in the manufacture of filtration equipment at home and abroad, and is widely used in petrochemical, fine chemical, chemical fiber, metallurgy, papermaking and special media filtration industries.

Category:

Melt filter

- Product Description

-

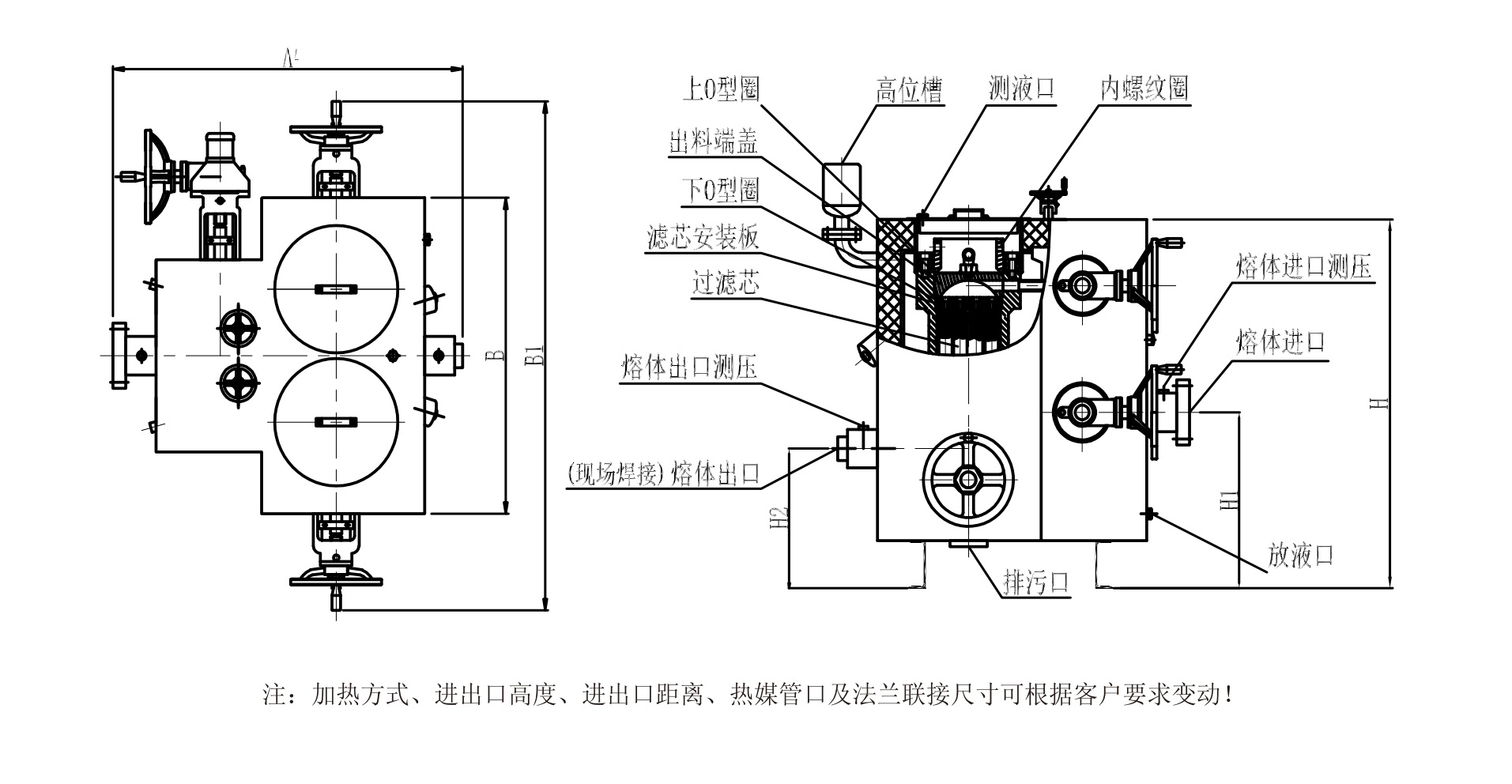

Product Features: Reasonable heating structure design, good heat preservation effect, and low energy consumption. No separate preheating is required; the filter chamber component can be hung into the main unit for preheating and heat preservation for 6-7 hours to reach the spinning process temperature. Manual turbine transmission is adopted for easier operation. Each cylinder is equipped with an exhaust discharge valve, which is simple to operate, has good safety performance, and ensures continuous and stable filament delivery without drifting.

Performance Range

Flow Rate

65-3700kg/h

Filter Area

0.6㎡- 19㎡

Operating Conditions

System Pressure

MAX25MPa

Allowable Pressure Difference

Max6Mpa

Jacket Pressure

≤0.25 Mpa

Operating Temperature

≤320°C

Applicable Scope

Polyester filament (POY, FDY), nylon (PA6, PA66, PA11) long and short filaments, nylon-polyester composite filaments, polypropylene spun-bonded and melt-blown nonwovens, polypropylene (P) long and short filaments, P spinning,

BOPET stretch film, spandex spinning, viscose fiber, plant fiber, etc. Its novel structure, low energy consumption, and wide adaptability make it suitable for various applications.Heating Method

Heat transfer oil circulation heating, combined circulation, heat transfer oil plus electric heating, and diphenyl electric heating are available.

Technical Parameters Table

Model

Pipe Diameter

(mm)Filter Area

(m1)Rated Flow Rate

(kg/h)Heating Power

(kw)Main Structural Dimensions

H

H1

H2

A

B

B1

CPF-PE-1.05S

30

1.05

65-90

7

1050

User Defined

User Defined

1020

750

1410

CPF-PE-1.26S

30

1.26

100-150

7

1100

1020

750

1410

CPF-PE-1.8S

30

1.8

160-190

7.5

1100

1080

870

1500

CPF-PE-2.5S

40

2.5

200-230

7.5

1150

1080

870

1500

CPF-PE-3.5S

40

3.5

240-340

9.2

1150

1170

930

1580

CPF-PE-4.5S

50

4.5

350-430

9.2

1200

1170

930

1780

CPF-PE-5.5S

50

5.5

440-490

9.7

1200

1250

1030

1880

CPF-PE-6.5S

50

6.5

500-550

9.7

1250

1250

1030

1980

CPF-PE-7.5S

50

7.5

560-650

10.8

1300

1320

1080

2030

CPF-PE-9.5S

65

9.5

660-850

11.5

1300

1350

1260

2160

CPF-PE-12S

65

12

860-1050

12.2

1450

1350

1260

2160

CPF-PE-15S

65

15

1050-1500

12.8

1710

1350

1260

2160

CPF-PE-31S

100

31

2200-3100

19.8

1820

1530

1480

2320

Structure Diagram

Keyword:

CPF-PE-S Melt filter

Previous page: Melt filter

Next page: CPF-DG-0.5F motor horizontal installation (meltblown fabric dedicated filter)

Product Inquiry

Please fill in the specific information, and we will contact you within 24 hours!