Hello, welcome to Jiangsu Main Machinery Technology Co., Ltd.!

Telephone:0510-86017899 Email:huangqindong@jszhjx.cn

Wedge wire filter / Metal wound filter

With its novel design, superb technology, and rigorous quality inspection, the product is unique in the manufacture of filtration equipment at home and abroad, and is widely used in petrochemical, fine chemical, chemical fiber, metallurgy, papermaking and special media filtration industries.

Category:

Liquid/water filtration

- Product Description

-

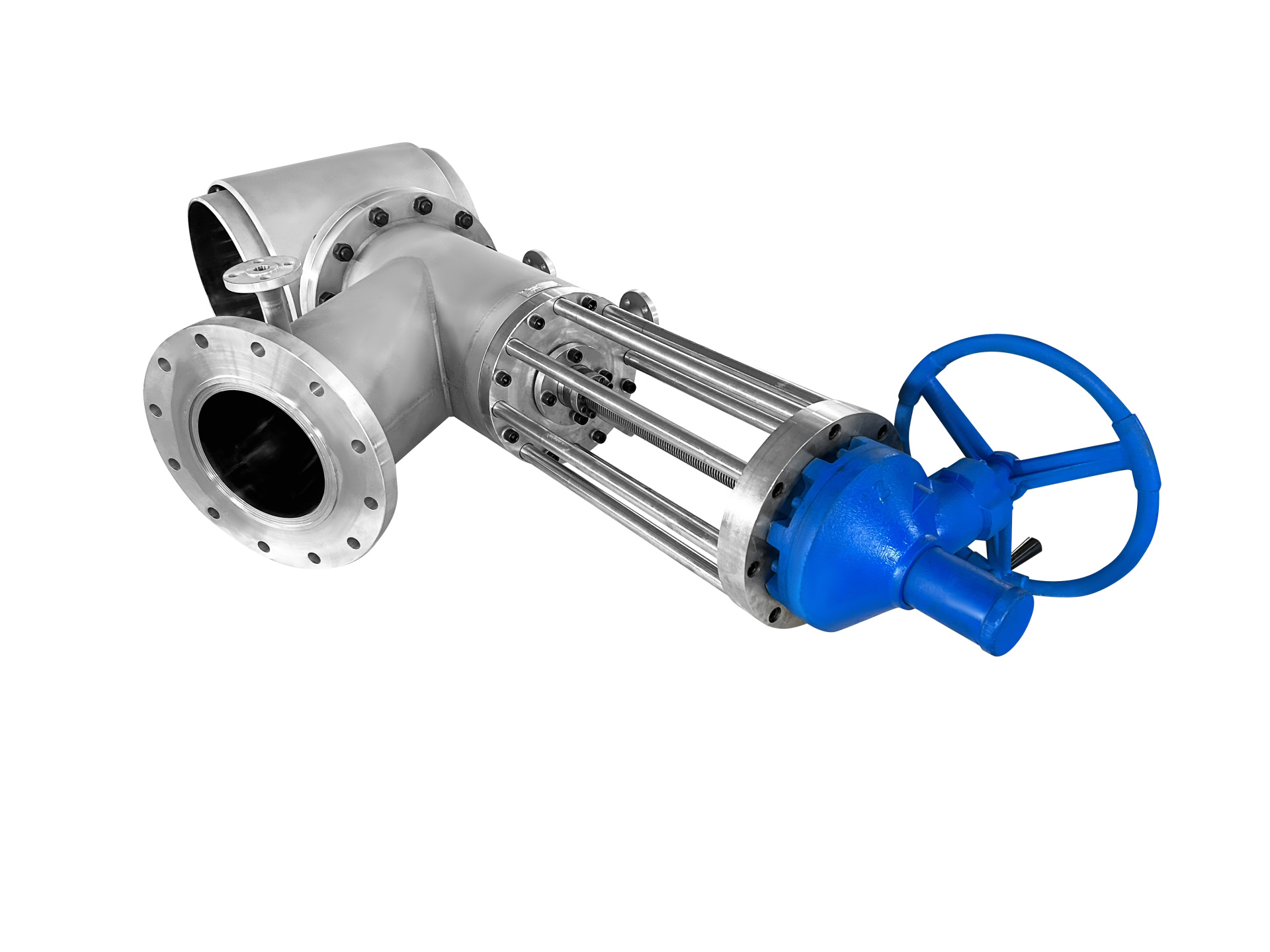

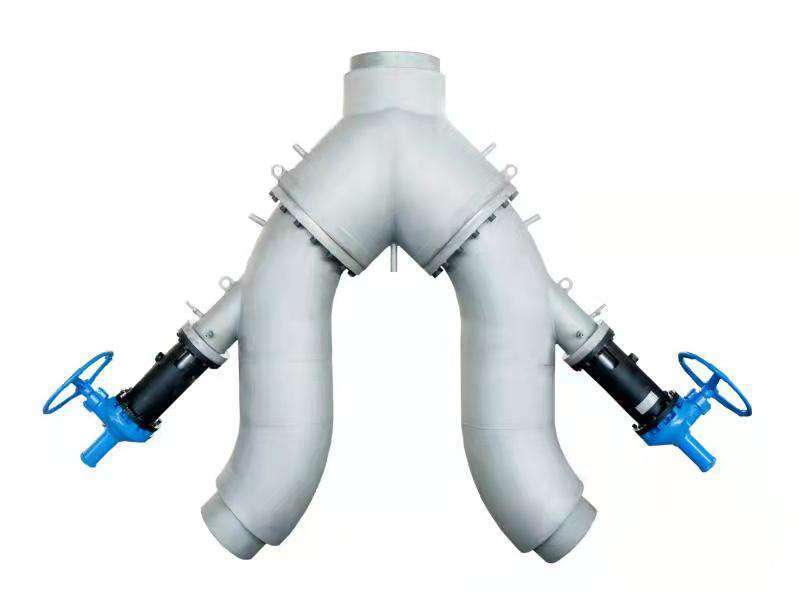

Wedge wire filters/metal wound filters are widely used in oil, gas, and water well sand control, and are particularly important in chemical and environmental industries. They are one of the most widely used types of filter screens in various oil and water resource recovery and collection, and resin filtration processes. It is the most widely used type of filter screen in the filtration screen tubes used in various oil and water resource recovery and collection, and resin filtration processes.Wedge wire filter elements (Johnson wound wire screens) adopt the world's most advanced all-welded production technology. They are made using specially made stainless steel trapezoidal (wedge-shaped) wires wound around a set of longitudinally arranged support rods in a circular arrangement, thus ensuring their strength and service life. Wedge wire filter elements (Johnson wound wire screens) have precise gap sizes, high filtration accuracy; they are sturdy, high-temperature resistant, corrosion-resistant, and have good mechanical properties, and can be used for filtering various media.Because of the full-process welding, not only is the strict continuous integrity of the product ensured, but also the ideal gap size is formed. Compared with the welding technology commonly used in China, the full-welded wedge wire wound wire screens, water filter pipes, water caps, water distributors, resin traps, and screen plates have smooth surfaces, no production edges, no burrs, and uniform gaps without resin leakage.Main Performance Parameters:Filtration accuracy: 25-800μm;Maximum working pressure: 0.4-10MPa;Maximum operating temperature: 80-300 °C;Number of filter elements that can be installed inside the filter cartridge: 1, 3, 5, 7, 9, 11, 13, 15...50, etc.;Filter element length: 10", 20", 30", 40";Material: 304, 316L, 904L, Hastelloy, etc.;Technical Parameter Table

Theoretical Flow Rate

Assembled Filter Elements

Inlet and Outlet Pipes

Connection Method

Specifications (mm)

t/h

Number

Length

Outer Diameter (mm)

0.3-0.5

1

10"

25

Quick Connect

φ50.5

0.5-1

20"

1-1.5

30"

1-1.5

1.5-33

10"

20"32

Quick Connect

φ50.5

2.5-4.5

30"

34

1.5-2.5

5

10"

32

Quick Connect

φ50.5

3-5

20"

4.5-7.5

30"

38

5-7

10"

38

φ50.5

6-10

8-147

20"

30"48

Quick Connect/Flanged

G1"

DN406-8

9

20"

48

Quick Connect/Flanged

φ64

G1.5"

DN508-12

30"

12-15

40"

6-12

20"

48

φ64

12-18

16-2412

30"

40"57

Quick Connect/Flanged

G1.5"

DN508-15

15

20"

76

Flanged

G2.5"

DN6518-25

30"

20-30

40"

12-21

21-31

27-4221

20"

30"

40"89

Flanged

G3"

DN80

Keyword:

Wedge wire filter / Metal wound filter

Previous page: Electric scraper self-cleaning filter / Pneumatic scraper self-cleaning filter

Next page: Insulated jacket liquid filter

Product Inquiry

Please fill in the specific information, and we will contact you within 24 hours!