Hello, welcome to Jiangsu Main Machinery Technology Co., Ltd.!

Telephone:0510-86017899 Email:huangqindong@jszhjx.cn

Sintered drill filter element: Cleaning and maintenance methods for fully automatic filters

Release Date:

2022-04-13

Sintered drill filter element: Cleaning and maintenance methods for fully automatic filters Fully automatic filters have four control methods: pressure difference control, manual control, time control, and PLC intelligent control. All control methods are simple and easy to operate, with a completely user-friendly design concept.

Sintered drill filter element Cleaning and maintenance methods for fully automatic filters

Fully automatic filters have four control methods: differential pressure control, manual control, time control, and PLC intelligent control. All control methods are simple and easy to operate, embodying a completely user-friendly design concept. The fully automatic filter boasts reliable intelligent control, automatically performing filtration, cleaning, and wastewater treatment, achieving unattended and uninterrupted water supply. The drainage time is very short, the pressure loss is small, and the water consumption is only 1% of the total water volume. Fully automatic filters cover a wide range of flow rates and precision levels and come in various structural forms to adapt to complex user working conditions. Its optimized control method design results in short backwashing times, saving time and effort in terms of wastewater discharge and water consumption, conserving water resources. Each parameter of the fully automatic filter can be adjusted according to the actual working conditions; it is easy to operate, maintenance-free, and has a long service life. Sintered drill filter element

Sintered drill filter element Cleaning and maintenance methods for fully automatic filters

1. When cleaning impurities, pay special attention to the stainless steel mesh on the automatic filter element. Otherwise, when reinstalling the filter, the purity of the filtered medium will not meet the design requirements, which may damage equipment such as compressors, pumps, and instruments.

2. After the automatic filter has been operating for a period of time, some impurities will settle in the filter element. At this time, the pressure drop will increase, and the flow rate will decrease, so it is necessary to clean the impurities in the filter element in time.

3. The core part of the automatic filter is the filter element, which consists of a filter frame and a stainless steel mesh. The stainless steel mesh is a consumable part and requires special protection. Sintered drill filter element

4. If the stainless steel mesh of the automatic filter is found to be deformed or damaged, it should be replaced immediately.

Sintered drill filter element Application workflow of fully automatic filters

The core component of the automatic filter is the filter element, which is made of special materials and is a fragile component that requires special protection. Automatic filters are more environmentally friendly and have higher efficiency. Automatic filters have high filtration accuracy, and to save water, the cleaning solution can reduce the amount of wastewater inflow. After the fully automatic filter has been operating for a period of time, the filter element will block a certain amount of impurities. When the pressure increases, the flow rate will decrease, so it is necessary to clean the impurities in the filter in time and clean the filter element at the same time. There are more than a dozen series of automatic filters currently available. Different types of automatic filters are used to handle different applications depending on the water quality and water lines. The working principle of the automatic filter is briefly introduced below. Sintered drill filter element

Sintered drill filter element Application workflow of fully automatic filters

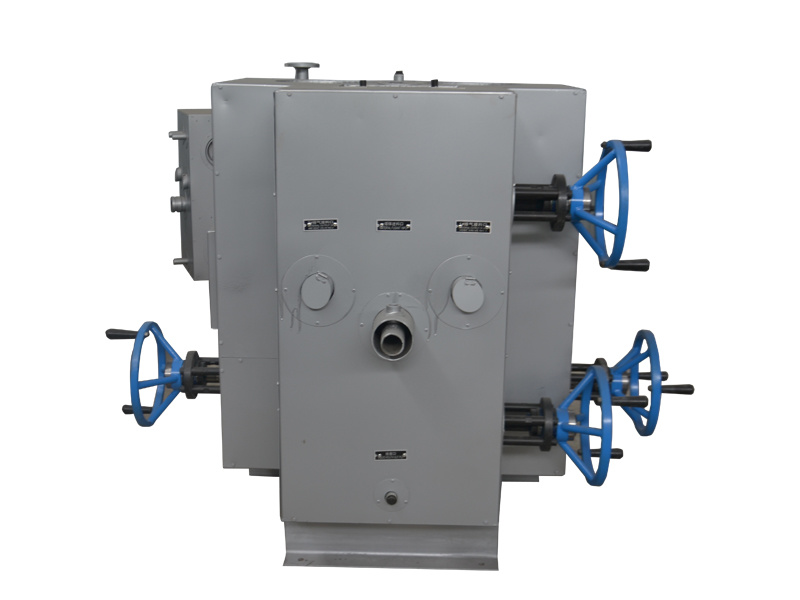

An automatic filter is a self-cleaning filter that filters through a filter screen. The automatic filter is mainly composed of important components such as a motor, filter screen, differential pressure switch, brush, and flange. When purchasing an automatic filter, attention should be paid to the quality assurance of wastewater filtration. The backwashing time of the automatic filter is only about 60 seconds. During the wastewater backwashing process, the water is constantly flowing, and the filter screen inside the automatic filter can filter various impurities in the water. Different filtration accuracy is closely related to the density of the filter screen. During the water filtration process, the automatic filter will generate pressure due to the filtration of impurities, thereby reducing the discharge of impurities before washing. During this period, the inside of the fully automatic filter remains stable. The backwashing filter can be assembled in the application scenario of the filter, with sizes up to 80 square meters and high demand.

→ Related News